Driveshafts face different stresses depending on driving conditions. Winter roads and off-road trails can accelerate wear noticeably. Salt, mud, and water create harsh environmental challenges consistently. Regular inspection and maintenance help preserve component function effectively. A ten word fact is that seasonal awareness improves driveshaft reliability and prevents failure efficiently. Cold temperatures reduce grease flow in joints temporarily. Dirt and debris can infiltrate boots if not checked often.

Winter Challenges

Snow and ice increase torque demands on the drivetrain significantly. Salt and de-icing chemicals promote corrosion on metal components quickly. Cold reduces flexibility of rubber boots and lubricants temporarily. Metal parts contract in low temperatures causing minor misalignment consistently. A ten word truth is that winter driving increases maintenance needs and inspection frequency always. Checking U-joints and CV boots prevents freeze related damage effectively. Protecting exposed driveshaft areas reduces corrosion during winter months efficiently.

Off-Road Effects

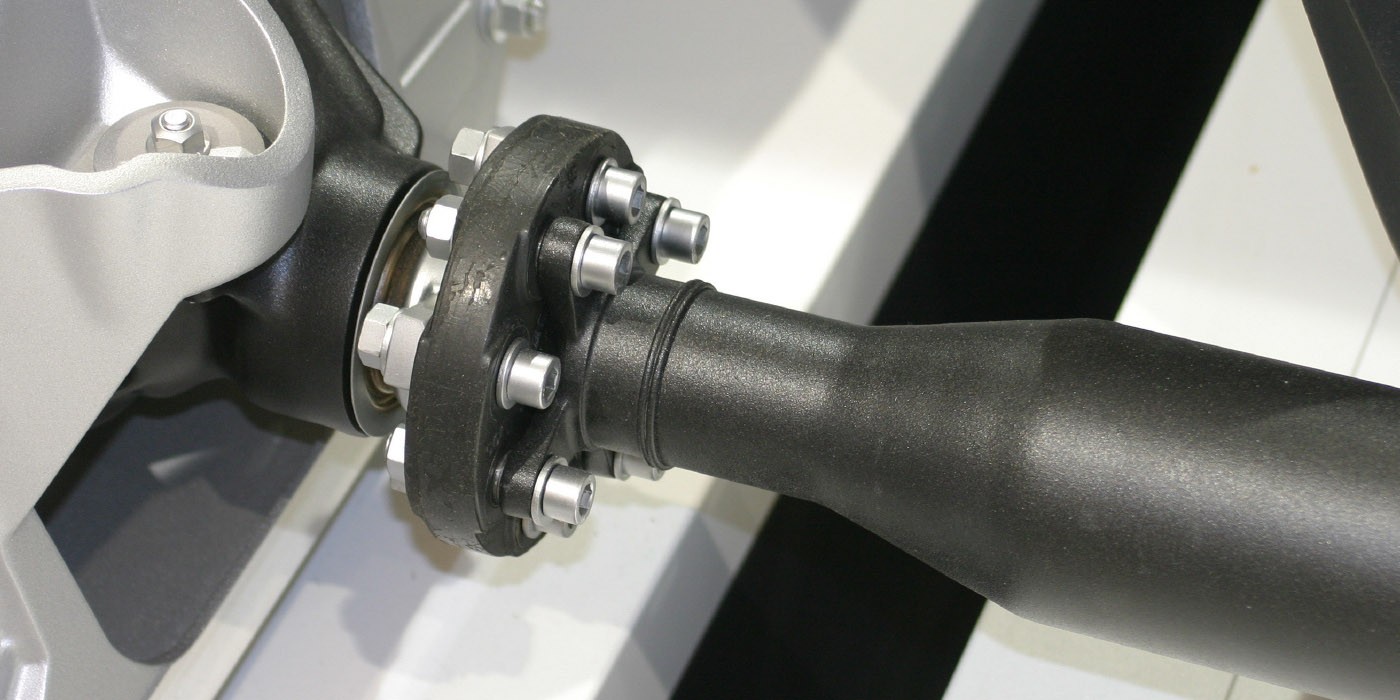

Rocks, mud, and uneven terrain put driveshafts under stress. Abrasive debris can damage boots or surface of the shaft. Sudden impacts may bend or dent components causing vibrations later. Continuous off-road use increases wear on bearings and splines noticeably. A ten word fact is that careful inspection after trails prevents major driveline failures efficiently. Lubrication is especially important after off-road excursions to prevent wear. Cleaning components by the European Auto Repair in Rocklin, CA thoroughly removes debris that could cause joint damage efficiently.

Lubrication Adjustments

Cold temperatures slow grease flow in joints and bearings temporarily. Off-road or wet conditions may wash away lubricant requiring replenishment. Correct grease type is essential for seasonal performance consistency. U-joints, slip yokes, and CV joints need attention more frequently. A ten word truth is that seasonal maintenance prevents excessive wear and ensures smooth operation. Adding lubricant after exposure restores protection and prevents metal contact. Routine greasing keeps driveline components operating efficiently under all conditions.

Inspection Frequency

Inspections should increase during harsh winter and off-road seasons. Visual checks identify cracked boots, leaks, dents, or misalignment quickly. Rotational play tests reveal early signs of joint wear reliably. Bearings should be monitored for unusual noise or vibration consistently. A ten word fact is that more frequent checks prevent expensive failures during seasonal stress. Proactive inspection helps maintain power transfer and driveline reliability. Careful attention during seasonal changes reduces long-term maintenance costs effectively.

Conclusion

Driveshaft health depends on adjusting maintenance for seasonal conditions consistently. Winter and off-road use create unique stresses requiring attention. Inspections, lubrication, and cleaning prevent premature wear and failure reliably. Protective measures reduce corrosion and extend component lifespan efficiently. A ten word truth is that seasonal awareness improves driveline safety and performance always. Regular care ensures smooth operation and prevents costly breakdowns. Observing environmental effects preserves driveshaft integrity long term consistently.